Precision Laser Cleaning: Grease & Oil Removal

At Perth Laser Cleaning, we provide advanced grease and oil removal services using cutting-edge laser technology to clean and restore industrial surfaces.

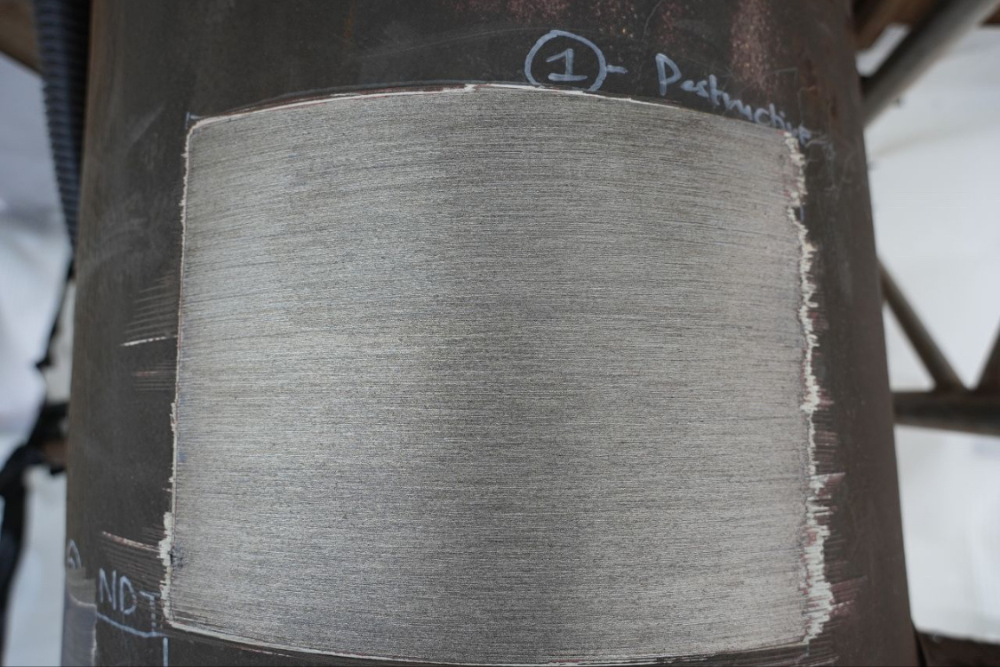

Our laser cleaning process effectively removes grease, oil, and other stubborn contaminants from metal, machinery, concrete, and other surfaces. This non-abrasive, eco-friendly method ensures thorough cleaning without damaging the underlying materials.

The precision of our laser technology ensures that even the most intricate or delicate surfaces are cleaned efficiently, making it an ideal solution for businesses that need fast and reliable results.

Benefits of Our Grease & Oil Removal Services

Non-Abrasive and Non-Damaging

Unlike traditional methods, such as sandblasting or chemical strippers, laser cleaning is gentle on surfaces, ensuring that the material underneath remains intact and undamaged.

Minimal Disruption

The laser cleaning process is non-invasive and requires minimal setup, allowing us to work around your business operations with minimal disruption, even in busy or high-traffic areas.

Precision Cleaning

Laser technology allows for highly targeted cleaning, focusing precisely on the area that needs attention. This results in clean surfaces without affecting adjacent areas.

Safe and Sustainable

Our service is not only safe for workers but also sustainable, contributing to cleaner, greener operations with no hazardous waste or pollutants released into the environment.

Why Choose Us for Grease & Oil Removal

Perth Laser Cleaning is the go-to choice for businesses seeking effective and safe grease and oil removal. Our advanced laser technology ensures that grease, oil, and other contaminants are removed thoroughly without causing harm to your equipment or surfaces. We prioritise eco-friendly, chemical-free methods that are safe for both your surfaces and the environment. With our fast, efficient service, we help reduce operational downtime, allowing your business to continue running smoothly and effectively.

Frequently Asked Questions

Our laser cleaning service is effective on a wide range of surfaces, including metal, concrete, stone, brick, plastic, and machinery, making it ideal for industrial and commercial applications.

Laser cleaning is faster, more precise, and non-abrasive, unlike traditional methods that can involve harsh chemicals or abrasive materials that could damage surfaces.

Yes, laser cleaning is gentle on delicate equipment and machinery. The process is non-damaging and can be precisely controlled to remove contaminants without harming the underlying surface.

The laser cleaning process is typically faster than traditional methods, and we can complete most jobs in a short amount of time with minimal disruption to your operations.

Yes, laser cleaning is completely chemical-free, making it an environmentally friendly solution for grease and oil removal, reducing hazardous waste and the use of toxic substances.